How to Choose the Right Pharmaceutical Machinery for Your Production Needs

Choosing the right pharmaceutical machinery is a critical decision that significantly impacts the efficiency and quality of production in the pharmaceutical industry. As industry expert Dr. Emily Carter once stated, "Selecting the appropriate machinery not only enhances productivity but also ensures the safety and efficacy of pharmaceutical products." This underscores the importance of thoroughly evaluating various machinery options to meet specific production needs while adhering to regulatory standards.

The process of choosing pharmaceutical machinery involves assessing several factors, including the type of formulations being processed, production volume, and the level of automation required. With advancements in technology, the range of machinery available has expanded, offering innovative solutions that improve operational efficiency. However, making an informed choice requires a deep understanding of the production requirements and the capabilities of different machines.

Ultimately, the right pharmaceutical machinery can lead to substantial benefits, including reduced production costs, improved product quality, and increased compliance with health regulations. Therefore, pharmaceutical manufacturers must approach this decision with careful consideration and comprehensive analysis, ensuring that their chosen equipment aligns with their strategic production goals and industry standards.

Understanding Your Production Requirements in Pharmaceutical Manufacturing

Understanding your production requirements in pharmaceutical manufacturing is crucial for selecting the appropriate machinery. Every production facility has unique needs based on the type of products being manufactured, the scale of operations, and specific regulatory compliance requirements. Start by assessing your production volume and the characteristics of your products. For instance, high-viscosity liquids may require different machinery compared to solid dosage forms.

Additionally, consider the desired level of automation and flexibility in your operations. A fully automated system may be beneficial for large-scale production, while smaller operations might prioritize modular machinery that can be easily adapted for different products. It’s also essential to evaluate the compatibility of equipment with the materials to be processed, as this can significantly impact efficiency and product quality.

By thoroughly understanding your production requirements, you can make informed decisions that align with your operational goals and ensure compliance with industry standards.

Types of Pharmaceutical Machinery and Their Functions

When selecting the right pharmaceutical machinery for your production needs, understanding the various types and their functions is crucial. The pharmaceutical manufacturing sector utilizes several types of machinery, including tablet press machines, capsule filling equipment, and liquid filling lines. According to a recent industry report by Grand View Research, the global pharmaceutical machinery market is projected to grow at a CAGR of 7.9% from 2021 to 2028, highlighting the increasing demand for efficient and precise manufacturing processes.

Tablet press machines play a vital role in the production of solid dosage forms, where powders are compressed into tablets. These machines can produce thousands of tablets per hour, making them essential for high-volume production settings. Additionally, capsule filling machines, which can fill both hard and soft capsules with powders, granules, or liquids, are critical for ensuring dosage accuracy and consistency. Recent studies indicate that the use of automated capsule filling systems can reduce production time by up to 30%, significantly improving operational efficiency.

Furthermore, liquid filling lines are increasingly being used for a diverse range of pharmaceutical products, including syrups and suspensions. These systems often incorporate advanced technologies such as volumetric or gravimetric filling to ensure precision and minimize wastage. Research from the International Journal of Pharmacy states that automated liquid filling machinery can achieve filling accuracy rates of over 99.5%, which is vital for maintaining quality standards in pharmaceutical production. Understanding these key machinery types and their capabilities is essential for making informed decisions that align with your manufacturing objectives.

How to Choose the Right Pharmaceutical Machinery for Your Production Needs

| Type of Machinery | Function | Key Features | Production Capacity |

|---|---|---|---|

| Tablet Press | Designs and compresses powder into tablets | High speed, adjustable pressure | Up to 200,000 tablets/hour |

| Liquid Filling Machine | Fills liquid products into containers | Adjustable fill volume, precise flow control | 200-500 bottles/minute |

| Capsule Filling Machine | Fills capsules with powder or pellets | Automatic operation, easy cleaning | Up to 100,000 capsules/hour |

| Blister Packaging Machine | Packages tablets/capsules in blisters | Automatic sealing, adjustable speed | Up to 300 blisters/minute |

| Granulator | Granulates powder for uniformity | Low noise, high efficiency | Up to 150 kg/hour |

Evaluating Performance and Efficiency of Pharmaceutical Equipment

When selecting pharmaceutical machinery, evaluating the performance and efficiency of equipment is crucial to ensuring optimal productivity and compliance. Key performance indicators (KPIs) such as throughput, accuracy, and downtime play a vital role in assessing machinery capabilities. Understanding the specific requirements of your production process will enable you to match these KPIs to the right equipment. Moreover, consider how well the machinery integrates into your existing workflow, as seamless operation can significantly enhance overall efficiency.

Tips: Regular maintenance checks on your pharmaceutical machinery can help identify potential inefficiencies before they lead to costly downtimes. Choosing equipment that offers real-time data tracking can also provide insights into performance metrics, allowing for quick adjustments to optimize production.

Efficiency is not just about speed; it also encompasses energy consumption and waste management. Evaluate how the machinery contributes to a sustainable production process. Look for equipment designed with energy efficiency in mind, as this can improve your overall operational costs while supporting environmental goals. Investing in technology that promotes minimal waste generation will not only enhance efficiency but also align with current industry standards for sustainability.

Performance and Efficiency of Pharmaceutical Machinery

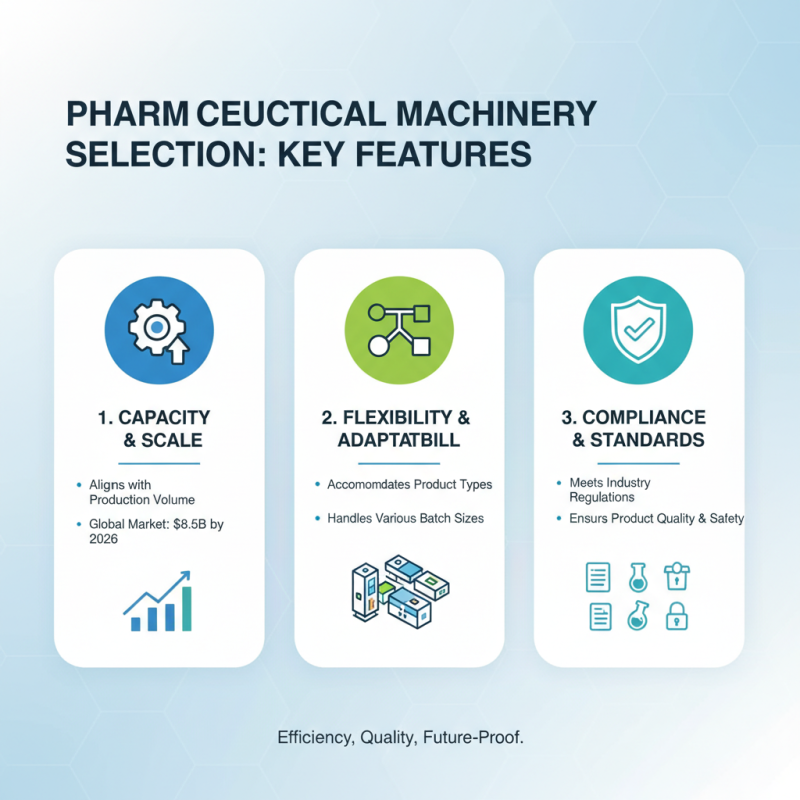

Key Features to Consider When Selecting Pharmaceutical Machinery

When selecting pharmaceutical machinery for production, several key features must be taken into account to ensure efficiency and compliance with industry standards. One crucial aspect is the machinery's capacity, which should align with the production scale. According to a recent industry report, the global pharmaceutical machinery market is expected to reach $8.5 billion by 2026, highlighting the growing demand for equipment that can handle varying production volumes. Flexibility in machinery design can significantly enhance adaptability to different product types and batch sizes, a feature increasingly desired in the fast-evolving pharmaceutical landscape.

Another essential consideration is the technology used in the machinery. Automation capabilities, for instance, can drastically improve production efficiency and reduce human error. A survey found that manufacturing companies that have adopted advanced automation technologies have seen productivity increases of up to 30%. Additionally, compliance with Good Manufacturing Practices (GMP) must be a priority; machinery should facilitate easy cleaning, maintenance, and validation processes to meet stringent regulatory requirements. Ultimately, the integration of advanced technology and adherence to quality standards are paramount to selecting the right pharmaceutical machinery for successful production outcomes.

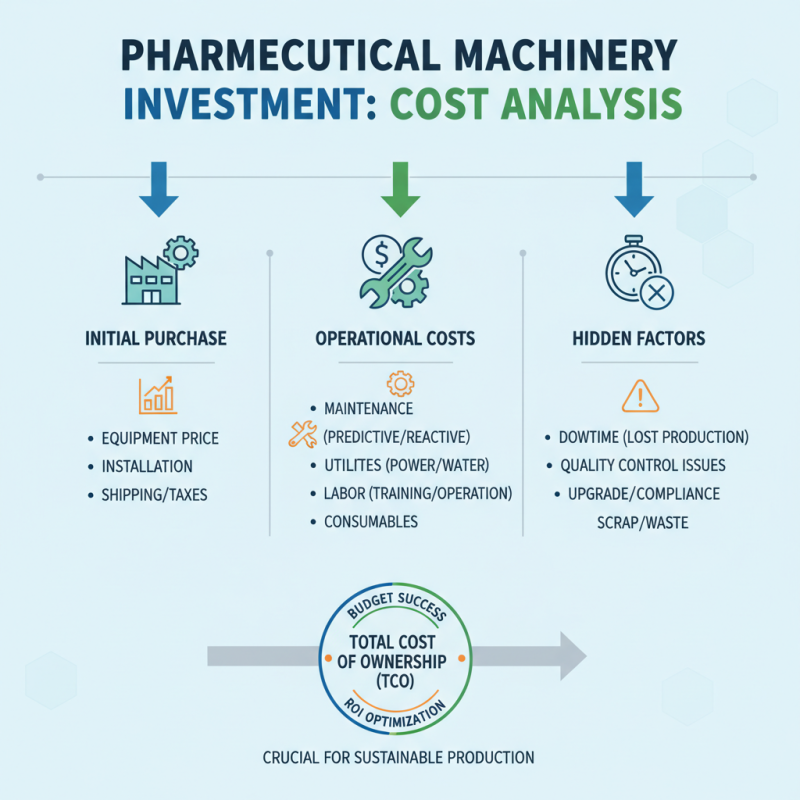

Budgeting and Cost Analysis for Pharmaceutical Equipment Investment

When investing in pharmaceutical machinery, budgeting and cost analysis are crucial steps that can impact the overall success of production operations. Understanding the total cost of ownership includes not only the initial purchase price of the equipment but also maintenance, operational efficiency, and potential downtime. Analyzing these cost factors helps manufacturers avoid hidden expenses that could disrupt budgets and timelines. It is essential to consider how different machinery can affect production rates and the quality of the final product, as these elements can significantly influence returns on investment.

Moreover, conducting a thorough cost-benefit analysis can illuminate the advantages of investing in advanced machinery versus maintaining older equipment. While new technology may require a higher initial investment, the long-term savings achieved through improved efficiency and lower operational costs can justify the expense. It’s important to project not only the immediate costs but also future operational needs as regulations change and production demands evolve. By accurately assessing these financial implications, companies can make informed decisions that align their equipment investments with both current requirements and future growth aspirations.

Related Posts

-

Ultimate Guide to Selecting the Best Pharmaceutical Processing Equipment for Your Needs

-

How to Optimize Efficiency in Pharmaceutical Processing Equipment

-

Innovative Trends in Pharma Equipment for Enhanced Pharmaceutical Manufacturing Efficiency

-

Top 10 Pharma Equipment Trends Revolutionizing Drug Manufacturing in 2023

-

Maximizing Efficiency in API Manufacturing with Digital Strategies and Key Industry Insights

-

10 Essential Insights for Pharmaceutical Manufacturing Success