How to Optimize Efficiency in Pharmaceutical Processing Equipment

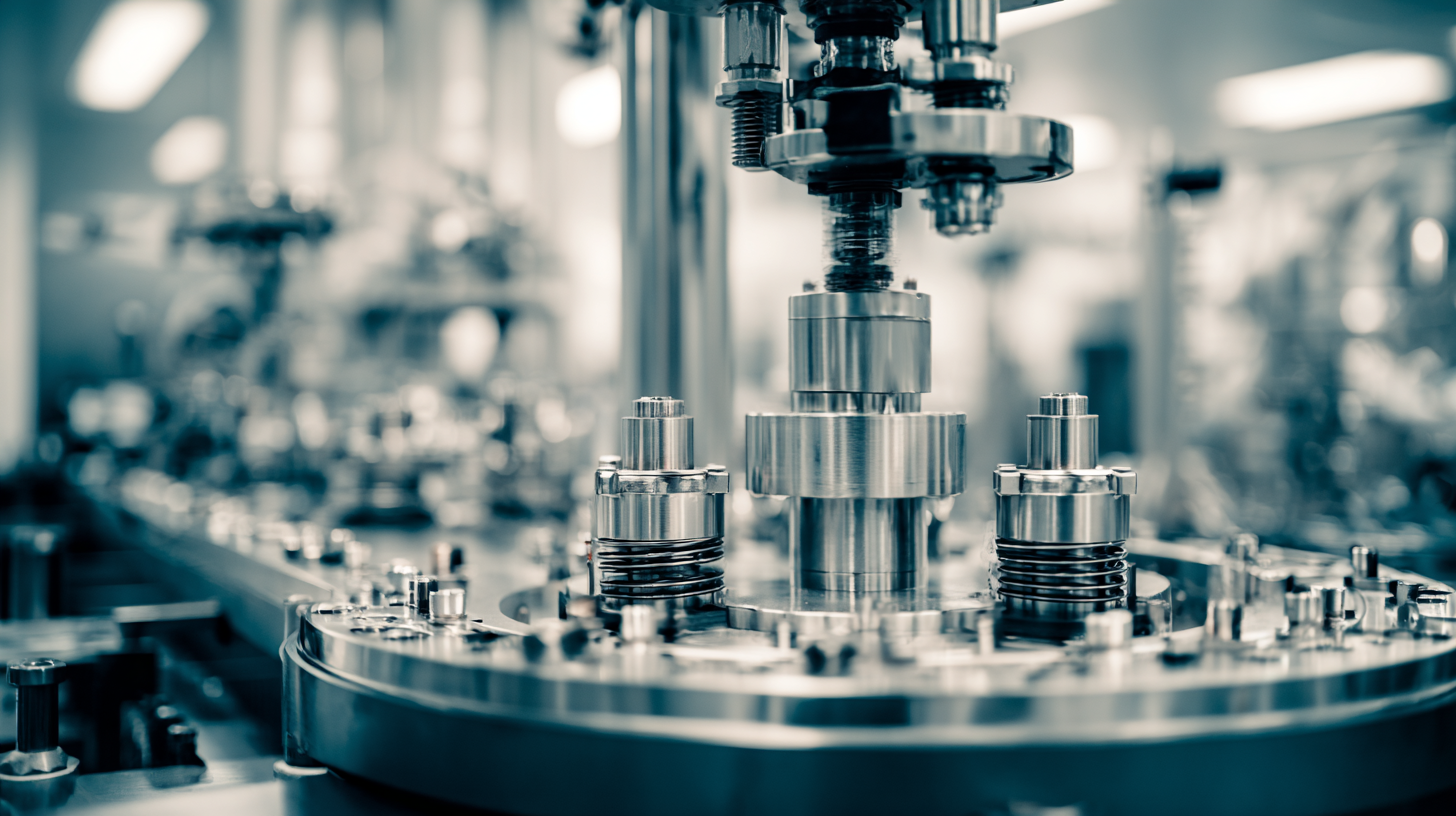

In the rapidly evolving pharmaceutical industry, optimizing efficiency in pharmaceutical processing equipment is crucial to maintaining competitiveness and meeting regulatory demands. According to a report by Markets and Markets, the global pharmaceutical equipment market is projected to grow from $35.9 billion in 2020 to $54.6 billion by 2025, reflecting an annual growth rate of 8.5%. This growth underscores the necessity for adopting advanced technologies and methodologies to enhance efficiency and reduce operational costs.

As pharmaceutical companies face increasing pressure to deliver high-quality products at lower prices, the integration of digital solutions such as automation and process analytics becomes essential. By leveraging these techniques, companies can not only streamline their operations but also ensure compliance with stringent regulatory standards, thus driving better outcomes in the production of pharmaceuticals.

Leveraging Data Analytics for Enhanced Equipment Performance in Pharma

Leveraging data analytics in pharmaceutical processing equipment presents a pivotal opportunity to enhance performance and efficiency. By analyzing data collected from various stages of manufacturing, companies can identify patterns and discrepancies that may not be immediately visible. For instance, predictive analytics can help anticipate equipment failures before they occur, reducing downtime and maintenance costs. This proactive approach allows manufacturers to optimize schedules, ensuring that equipment is used to its maximum potential.

Moreover, real-time data monitoring enables pharmaceutical companies to continuously track operational parameters, ensuring they remain within established specifications. By employing advanced analytics tools, businesses can refine their processes, leading to improved product quality and compliance with regulatory standards. Integrating data analytics into equipment performance not only streamlines operations but also fosters a culture of innovation, where insights derived from data can drive strategic decisions and enhance overall productivity.

How to Optimize Efficiency in Pharmaceutical Processing Equipment - Leveraging Data Analytics for Enhanced Equipment Performance in Pharma

| Equipment Type | Downtime (%) | Maintenance Costs ($) | Production Volume (Units) | Efficiency (%) | Data Analytics Used |

|---|---|---|---|---|---|

| Tablet Press | 5 | 2000 | 50000 | 90 | Vibration Analysis |

| Mixing Tank | 3 | 1500 | 30000 | 85 | Temperature Monitoring |

| Filling Machine | 4 | 1800 | 40000 | 92 | Flow Rate Analysis |

| Packaging Line | 6 | 2500 | 20000 | 88 | Image Recognition |

| Sterilizer | 2 | 2200 | 25000 | 95 | Process Validation |

Integrating IoT Solutions for Real-Time Monitoring and Control in Processing

The integration of IoT solutions in pharmaceutical processing equipment is revolutionizing the industry by enabling real-time monitoring and control. As the demand for efficient and precise manufacturing processes grows, the market for process control systems is expected to expand significantly. According to recent industry analyses, the distributed control systems (DCS) and programmable logic controllers (PLC) segments are projected to witness substantial growth, driven by advancements in automation technologies. By 2032, the process control market is anticipated to see a compound annual growth rate of approximately 8.5%, making it critical for pharmaceutical manufacturers to embrace these technologies.

In conjunction with this growth, artificial intelligence is increasingly being utilized to enhance monitoring capabilities within these systems. The AI video surveillance market, which surpassed $5.5 billion in 2023, is expected to grow at a CAGR of around 15.5% from 2024 to 2032, bolstered by the integration of edge computing. This trend indicates a shift towards more intelligent processing solutions that not only optimize equipment performance but also ensure compliance with stringent regulatory requirements in the pharmaceutical sector. Such advancements will play a pivotal role in improving overall operational efficiency and product quality in pharmaceutical manufacturing.

Implementing Best Practices for Preventive Maintenance in Pharmaceutical Equipment

Preventive maintenance is crucial in ensuring the optimal efficiency of pharmaceutical processing equipment. By implementing a structured maintenance schedule, facilities can minimize downtime and reduce the risk of equipment failure. This includes routine inspections, regular calibrations, and timely replacements of worn-out parts. Establishing a checklist for equipment maintenance tasks helps technicians systematically address potential issues before they escalate, thereby enhancing overall productivity.

Additionally, training personnel on the best practices for maintenance is essential. Staff should be well-versed in operating protocols and preventive techniques to recognize early signs of wear or malfunction. Utilizing data analytics can further aid in identifying patterns of equipment performance, allowing for predictive maintenance strategies that anticipate failures before they occur. This proactive approach ensures that pharmaceutical operations run smoothly, ultimately contributing to the safety and quality of the products manufactured.

Utilizing Automation Technology to Streamline Production Processes

In the realm of pharmaceutical manufacturing, streamlining production processes is crucial for maintaining efficiency and ensuring product quality. Automation technology plays a pivotal role in this optimization, transforming traditional manufacturing lines into smart, responsive systems that can adapt to changing demands. By integrating automation, companies can minimize human error, enhance precision, and ultimately accelerate production timelines.

Tips for implementing automation effectively include starting with a thorough assessment of current processes. Identify bottlenecks and areas where manual intervention slows down production. Secondly, consider investing in modular automation solutions, which allow for incremental upgrades without overhauling entire systems. This flexibility can lead to significant time and cost savings. Finally, ensure that staff is well-trained in these new technologies to maximize their potential and foster a culture of continuous improvement.

As automation evolves, leveraging data analytics becomes imperative. Real-time monitoring of equipment performance enables proactive maintenance, reducing downtime and extending the lifespan of your machinery. By adopting these strategies, pharmaceutical companies can achieve greater efficiency and responsiveness, laying the foundation for long-term success in a competitive industry.

Pharmaceutical Processing Efficiency: Automation Impact

This chart illustrates the improvement in production efficiency in pharmaceutical processing before and after the implementation of automation technology. As seen, automation significantly enhances efficiency from 65% to 90%.

Enhancing Workflow Efficiency through Employee Training and Collaboration Techniques

To enhance workflow efficiency in pharmaceutical processing, one of the most effective strategies is to invest in comprehensive employee training. Training programs should not only cover the technical aspects of operating pharmaceutical equipment but also focus on best practices and standard operating procedures. By equipping employees with the knowledge and skills they need, organizations can minimize errors and streamline processes, leading to improved overall productivity.

Collaboration techniques also play a critical role in optimizing efficiency. Encouraging open communication among team members fosters a culture where knowledge is shared and problems are addressed promptly. Regular team meetings and collaborative problem-solving sessions can help staff identify bottlenecks in workflow and develop innovative solutions together. By creating an environment that values cooperation, pharmaceutical companies can ensure that each member is aligned with organizational goals and that tasks are carried out more effectively.

Related Posts

-

Unlocking the Secrets of Best Pharmaceutical Manufacturing Technical Specifications and Key Sourcing Strategies

-

The Ultimate Guide to API Manufacturing: Unlocking Efficiency in Pharmaceutical Production

-

How to Choose the Right Pharmaceutical Solutions for Your Business Needs

-

Unlocking the Advantages of API Manufacturing for Enhanced Product Quality

-

How to Optimize API Pharmaceutical Development for Maximum Efficiency

-

Ultimate Guide to Choosing the Right Tablet Coating Machine for Your Production Needs