The Future of Tablet Manufacturing Machines Innovations Shaping the Industry

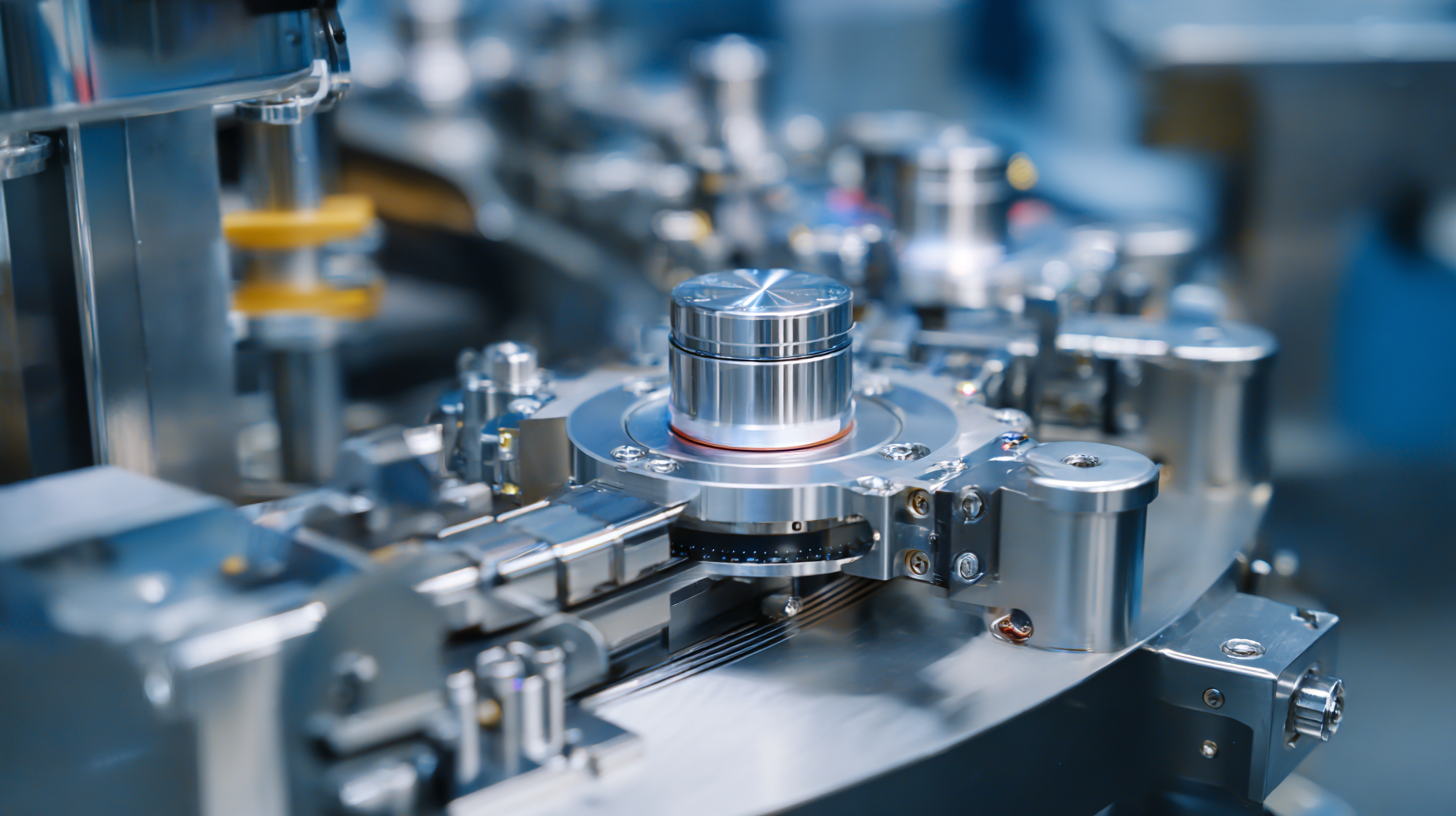

The landscape of tablet manufacturing is undergoing a significant transformation, driven by innovative advancements in technology and production processes. As the demand for efficient and high-quality pharmaceuticals continues to rise, the focus on enhancing tablet manufacturing machines has become paramount. These machines are not just essential for producing tablets, but they also play a critical role in ensuring the consistency and reliability of the final product. In this article, we will explore the latest innovations that are shaping the tablet manufacturing industry, including automation, advanced materials, and sophisticated quality control systems. By understanding how these technological breakthroughs are revolutionizing tablet production, manufacturers can better prepare for future challenges and opportunities, ultimately leading to more efficient and sustainable practices in both production and supply chain management.

Innovative Technologies Driving Tablet Manufacturing Efficiency and Quality

The tablet manufacturing industry is on the brink of a

technological revolution, driven by innovative technologies that enhance efficiency and elevate product quality. One primary advancement is the integration of

automation and robotics throughout the manufacturing process. These systems not only streamline production lines but also reduce human error, ensuring consistent tablet formation and higher output.

Automated quality control systems equipped with artificial intelligence analyze each tablet for defects in real-time, leading to significant decreases in waste and the assurance of uniform product standards.

The tablet manufacturing industry is on the brink of a

technological revolution, driven by innovative technologies that enhance efficiency and elevate product quality. One primary advancement is the integration of

automation and robotics throughout the manufacturing process. These systems not only streamline production lines but also reduce human error, ensuring consistent tablet formation and higher output.

Automated quality control systems equipped with artificial intelligence analyze each tablet for defects in real-time, leading to significant decreases in waste and the assurance of uniform product standards.

Moreover, the implementation of advanced materials and processes, such as continuous manufacturing techniques, is transforming traditional batch production methods. This innovation allows for a more flexible, faster production cycle, accommodating varying tablet formulations without extensive downtime. With the rise of

3D printing in pharmaceuticals, manufacturers can also create personalized tablets tailored to individual patient needs. These cutting-edge developments collectively promise to

redefine the landscape of tablet manufacturing, making it not only more efficient but also capable of meeting modern healthcare demands with enhanced precision and speed.

The Role of Automation in Enhancing Production Output for Tablet Machines

The role of automation in tablet manufacturing is becoming increasingly critical as industries demand higher production outputs and improved efficiency. Automated machinery not only expedites the production process but also enhances accuracy in dosage and consistency, which are vital for pharmaceutical applications. By integrating advanced robotics and artificial intelligence into tablet presses and coating machines, manufacturers can optimize workflows, reduce human error, and minimize downtime, ultimately leading to a more streamlined production cycle.

Moreover, automation facilitates real-time data collection and analysis, allowing manufacturers to monitor processes closely and make adjustments on-the-fly. This capability leads to better resource allocation and waste reduction, contributing to sustainability goals. As the tablet manufacturing landscape continues to evolve, embracing automation is essential for staying competitive, meeting regulatory compliance, and responding swiftly to market demands. The future lies in machines that not only perform tasks with precision but also learn and adapt, pushing the boundaries of what is possible in tablet production.

Sustainable Manufacturing Practices: Reducing Waste in Tablet Production

Sustainable manufacturing practices are becoming increasingly critical in tablet production, not only to minimize waste but also to enhance efficiency. Recent studies project that innovative equipment will reduce agricultural waste by 30% in food manufacturing by 2025, illustrating the potential for similar advancements in the pharmaceutical sector. The shift towards continuous manufacturing processes, exemplified in tablet production, allows for significant reductions in energy consumption and resource use, further contributing to sustainability goals.

Incorporating automation and data-driven decision-making is key to achieving success in this arena. By leveraging artificial intelligence and big data analytics, manufacturers can enhance quality control and optimize production, minimizing unplanned downtime and improving overall operational efficiency. Emerging technologies not only enhance production flow but also ensure that waste reduction becomes a strategic imperative rather than a mere option.

Tips: Consider implementing automation technologies that can monitor real-time data to identify inefficiencies. Regularly assess your production processes to locate opportunities for waste reduction. Engaging in continuous training regarding sustainable practices can empower employees and instill a culture of sustainability within your organization.

Emerging Materials and Their Impact on Tablet Manufacturing Equipment

The tablet manufacturing industry is on the cusp of a significant transformation, largely driven by the emergence of innovative materials that are redefining equipment standards. Advanced materials such as nanomaterials and polymers are increasingly being integrated into manufacturing machines, offering enhanced durability and efficiency. These materials not only reduce wear and tear on machinery during production but also contribute to more precise tablet formation, which is crucial for dosage accuracy in pharmaceuticals.

Moreover, the adoption of smart materials is enabling the development of multi-functional tablet manufacturing equipment. For instance, machines that utilize shape-memory alloys can adapt to different production needs, optimizing the manufacturing process in real-time. This adaptability streamlines operations, reduces downtime, and ultimately leads to a more sustainable production environment.

As manufacturers embrace these novel materials, the landscape of tablet production will continue to evolve, ushering in new possibilities for innovation and efficiency in the industry.

Market Trends: Data on Global Tablet Production Forecasts and Machine Demand

The global tablet market is expected to experience substantial growth, with projections indicating that its size will reach $3.01 billion by 2024 and expand to approximately $5.19 billion by 2035, reflecting a compound annual growth rate (CAGR) of 5.6%. This growth trajectory is influenced by heightened demand for tablets in various sectors, including education, healthcare, and entertainment, fostering innovations and advancements within the tablet manufacturing machines.

As the tablet production landscape evolves, so too will the machinery required for efficient manufacturing. The global market for photolithography equipment is forecasted to rise remarkably, with expectations of increasing from $27.66 billion in 2024 to $55.13 billion by 2032, representing a CAGR of 9.0%. This boom underscores the necessity for manufacturers to adopt cutting-edge technologies in their production lines to remain competitive and meet the escalating demands of the tablet market. The interplay between market growth and machine innovation will significantly shape the future of tablet manufacturing, driving enhancements in quality and production efficiency.

The Future of Tablet Manufacturing Machines Innovations Shaping the Industry

| Year | Global Tablet Production (Million Units) | Machine Demand (Units) | Market Growth Rate (%) |

|---|---|---|---|

| 2023 | 180 | 25,000 | 4.5 |

| 2024 | 190 | 27,000 | 5.0 |

| 2025 | 200 | 30,000 | 5.2 |

| 2026 | 210 | 32,500 | 4.8 |

| 2027 | 220 | 35,000 | 5.0 |

Related Posts

-

How to Choose the Right Tablet Manufacturing Machine for Your Production Needs

-

Ultimate Guide to Choosing the Right Tablet Coating Machine for Your Production Needs

-

How to Choose the Right Pharmaceutical Solutions for Your Business Needs

-

5 Best APIs Reshaping the Future of the Pharmaceutical Industry

-

10 Essential Insights for Pharmaceutical Manufacturing Success

-

Understanding the Role of API in Pharmaceutical Industry Innovation and Development